The following schematics are for illustrative purposes to explain the basic mechanics of the rotating cylinder bank of the Rotodyne Engine with comparisons to traditional ICEs having stationary cylinders banks. Click here to see the same demonstration on our older Flash website (requires a desktop computer and a Flash plug-in –it’s worth the effort).

ICE Configuration

A traditional internal combustion engine (ICE) uses a 4-stroke combustion cycle to move a piston in a stationary cylinder. A rod connects the piston to the crankshaft to transfer the linear motion of the piston into circular motion

V-8 Configuration

A traditional ICE utilizes an array of stationary cylinders. They can be positioned in-line, opposing or in a V-formation to drive the crankshaft.

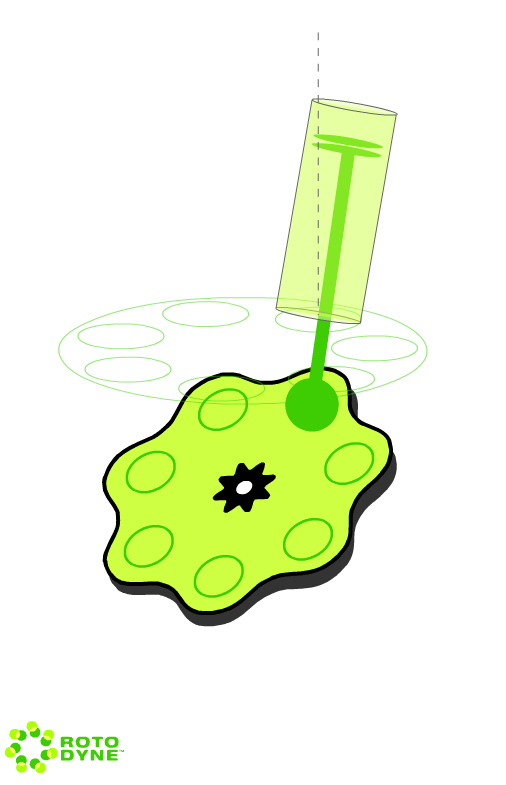

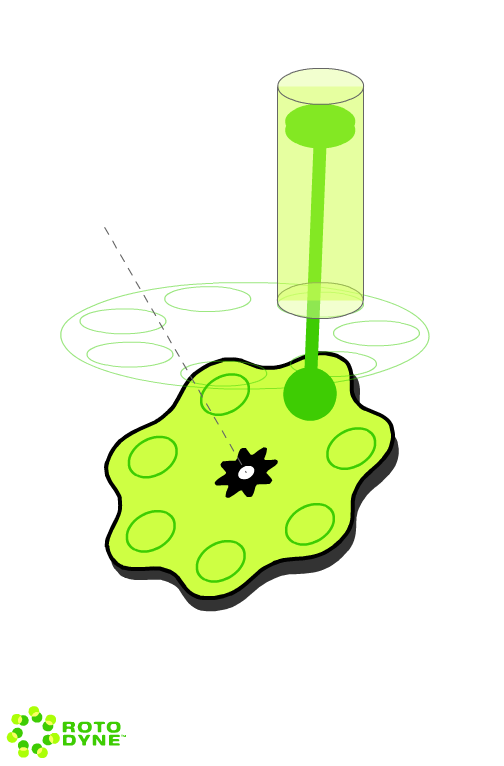

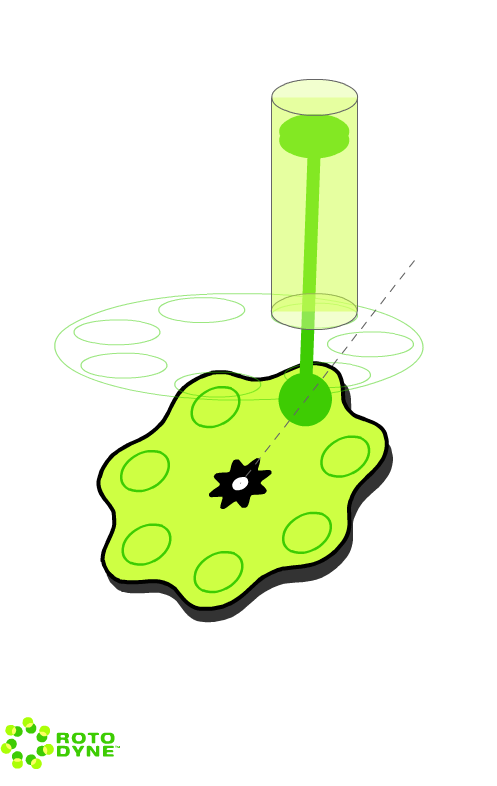

Rotodyne Configuration

The Rotodyne Engine employs an odd number of cylinders in a circular or ‘barrel” configuration. The crankshaft is replaced by a torque plate. The torque plate is placed at an oblique angle opposite the cylinders. The torque plate and the cylinder bank are connected by a synchronizing gear so that they rotate at the same speed.

Optimizable Components to Customize Piston Dwell

Rotodyne Engines, LLC discovered that the 2 degrees of freedom of motion that a rotating cylinder bank employs, allowed us to discover many design variables which decouple the piston motion from the crank angle and thereby affords several optimizable design variables which form the heart of US patent 7,677,210, and which are as follows:

The tilt of the cylinder in the both and X and Y dimensions (denoted as Pitch & Yaw and measured in inches)

The Offset of the Torque Plate in the X and Y dimensions (measured in inches).

The Tilt/Rotation of the torque plate in the X and Y dimensions (measured in inches).

The Advance / Retardation of the torque plate in relation to the cylinder bank (measured in degrees)

Constant Volume Combustion

The Rotodyne configuration provides design flexibility to optimize the piston movement within the cylinder to effectuate Constant Volume Combustion. Constant volume combustion is the ideal combustion cycle and heretofore impossible to achieve with a stationary cylinder bank.

The Rotodyne Advantage

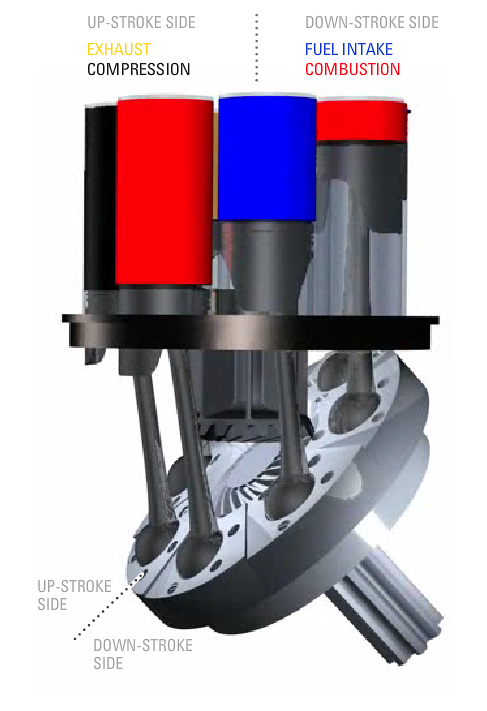

One-Cylinder Actuation

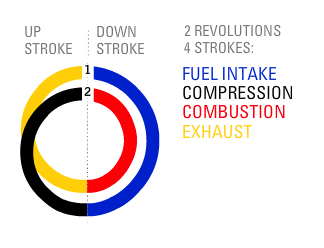

The Rotodyne engine operates with a traditional Otto 4-stroke cycle in the course of 2 revolutions of the cylinder bank. Intake and power strokes occur on the down-stroke side of the engine. Compression and exhaust strokes occur on the up-stroke side of the engine

All Cylinders

All Cylinders

An odd number of cylinders permits sequential actuation as follows: 1,3,5,7,2,4,6,1,3 … While the illustration is for a 7 cylinder engine, the actual prototype will be a 5 cylinder engine.

Overview of Fuel Intake & Exhaust

The cylinder head rotates with the cylinder assembly and channels and regulates fuel and exhaust gases.

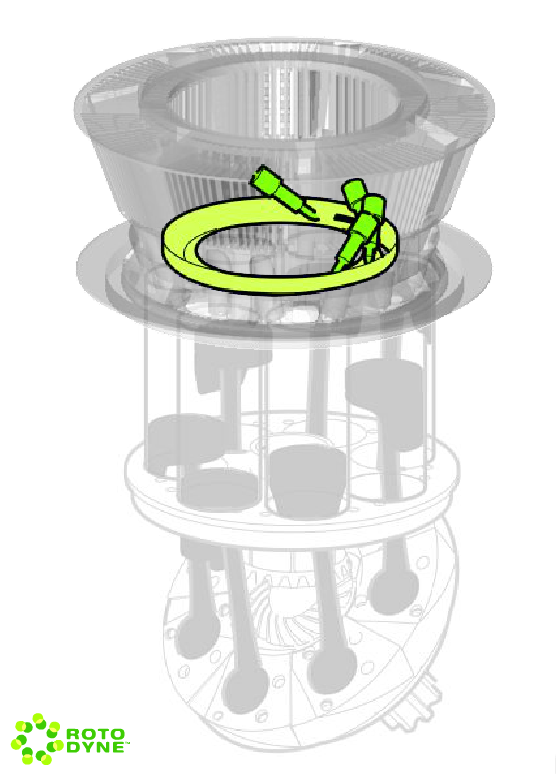

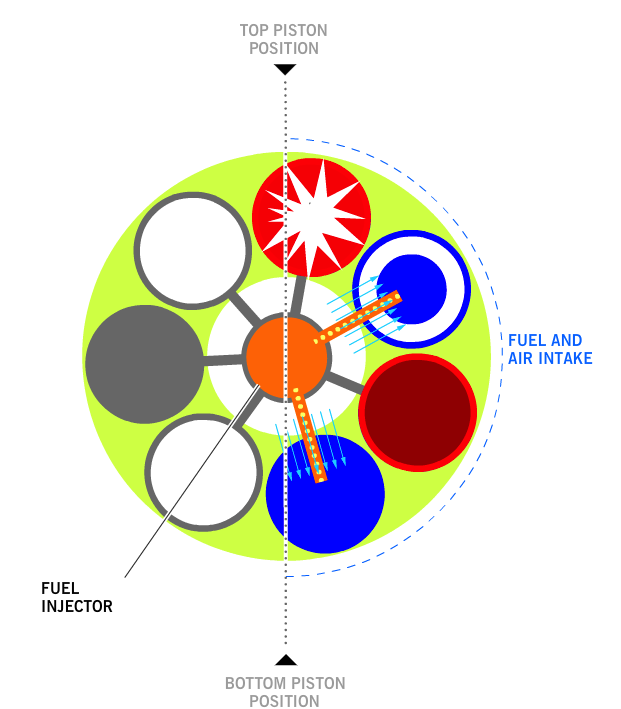

Fuel Intake

Cam Tracks

Valves

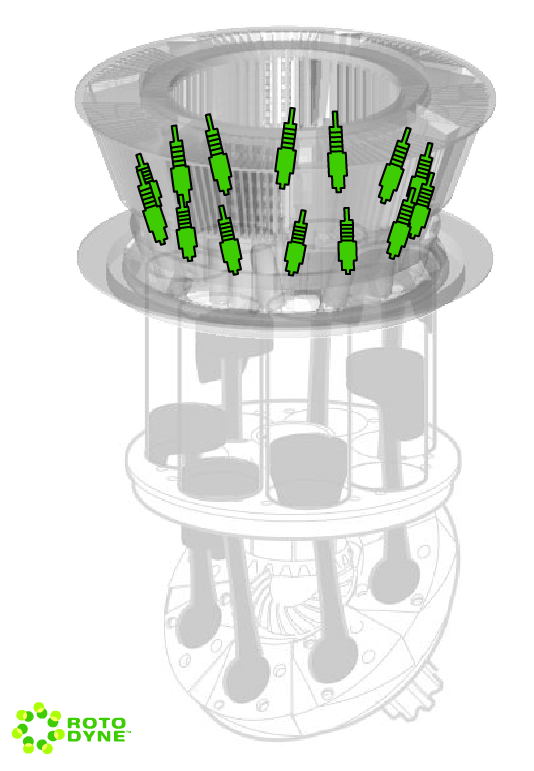

SparkPlugs

Fuel Intake

A high pressure, stationary fuel pump is positioned in the center of the cylinder head to deliver fuel to every other cylinder in one of the following ways:

- Homogenous charge (shown). Fuel is delivered to fuel injectors placed adjacent the valves so that fuel is injected into the cylinders during the fuel intake part of the stroke and thus charges the fuel with air.

- Direct Injection. Fuel is delivered to fuel injectors placed in each cylinder. This happens after compression when ignition takes place.

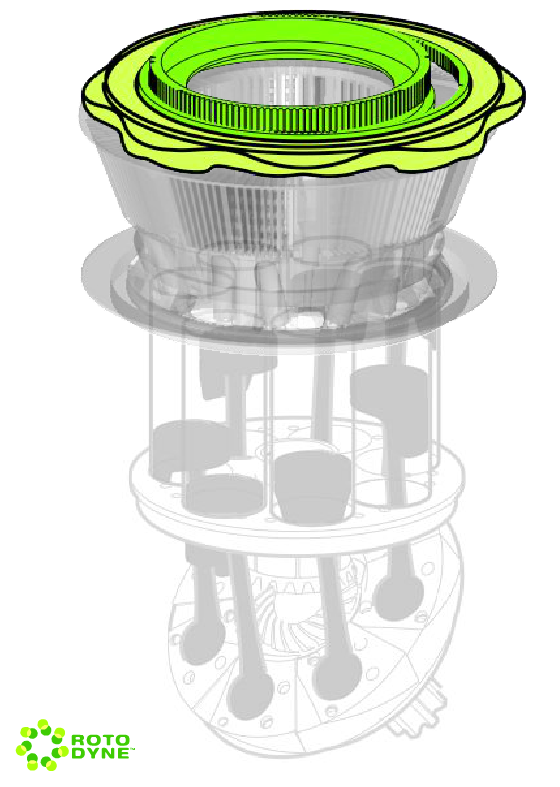

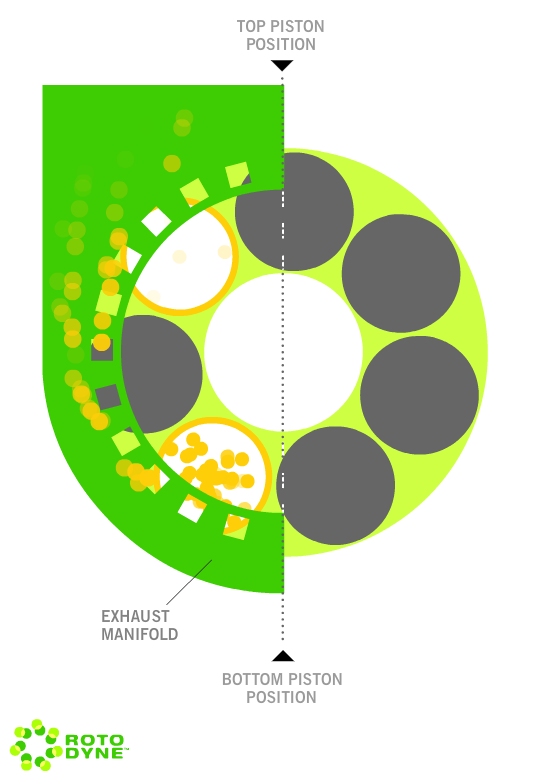

Exhaust Manifold

The stationary exhaust manifold surrounds the rotating cylinder head at the up-stroke side of the engine and operates with the exhaust valves. Every other cylinder valve is open while in exhaust mode.

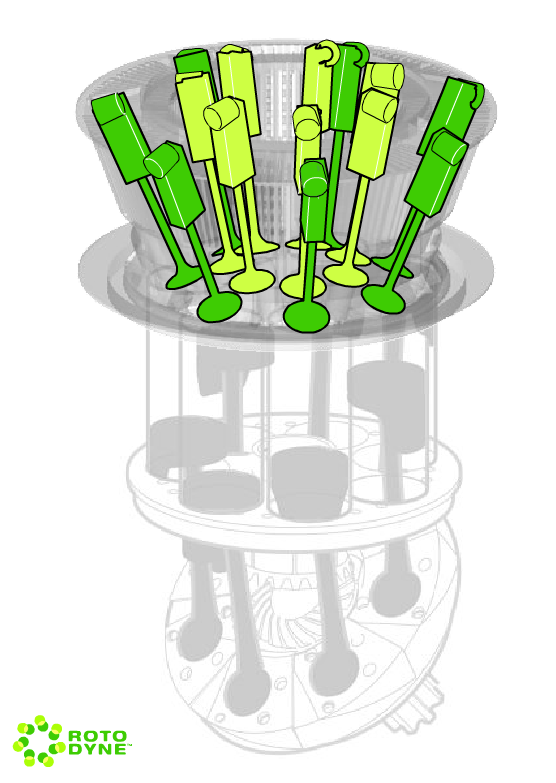

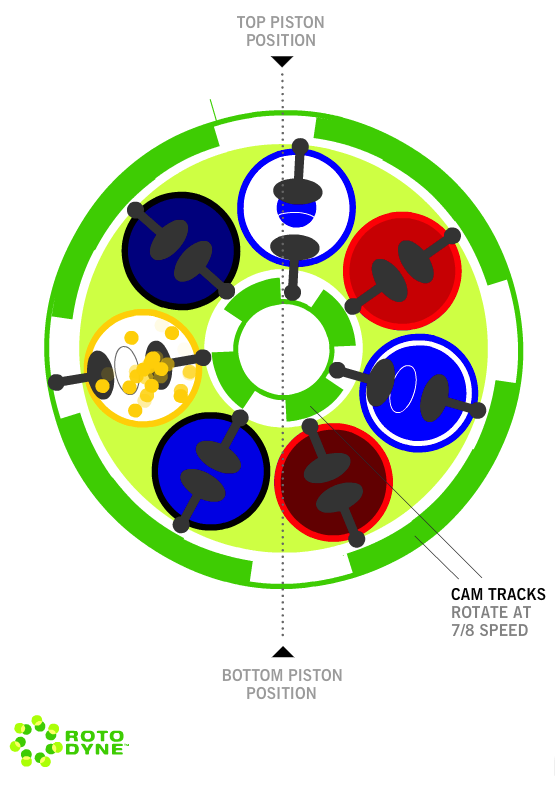

Valves & Cam Tracks

Separate cam tracks actuate the intake and exhaust valves. Each cam track has 8 sections with alternating surface levels. The cam tracks rotate at ⅞ the speed of the cylinder band so that the valve lifters match up with an alternate part of the cam at the right moment to open or close the valve.

Cooling Mechanics

Air Cooling

The rotation of the engine, aided by fans, pulls in cooling air. The air is directed over the center of the engine and is led past the cylinder fins to pull heat out of the engine.

Liquid Cooling

Liquid cooling of the engine is achieved using a stationary channel running up through the bottom of the torque plate and a rotating seal which allows the liquid to rotate with the cylinder carriage to effectuate heat exchange with the cylinders and head unit.

Benefits

The benefits of a more efficient internal combustion engine are many, and depend on the application.

Rotodyne Engine Development, LLC is now executing a distributed engine development strategy to partner with independent engine builder(s) to build and test a prototype of the revolutionary Rotodyne Engine, in order to then sell and/or license the technology under US Patent 7,677,210, which is the pioneering patent for constant volume combustion. All engine builder participants will receive a share of the profits and proceeds from all sales and licensing.

The Rotodyne Engine is set to disrupt the $500B standby generator market. It is the first and most practical multi-cylinder engine to employ the textbook constant volume combustion cycle. Other markets and applications worldwide provide further incentive.

Interested parties should contact us.